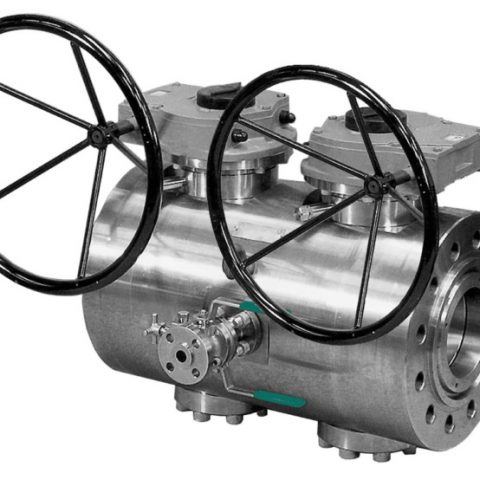

the oliver twinsafe h2g series of floating and trunnionmounted ball valves have been specially developed for the requirements of hydrogen applications.

oliver has developed its own unique qualification program that exceeds current industry standards to ensure they are the market leader in this rapidly expanding industry sector.

the valves are available with zero through seat leakage in both soft and metal seated designs, with specially selected materials of construction to ensure full compatibility with hydrogen.

valve design: api 6d, api 6a

pressure class: asme class 150 – 600

temperature range: -40℃ to 121℃

end connections: flanged, butt weld, hub

size range: 1 to 18 in (dn25 to dn500)

design features

bubble tight through seat leakage – soft or metal seats

forged 1 piece compact body, 2 piece or 3 piece body designs

high integrity coating of ball and seats for metal seated designs

bi-directional sealing

single isolate, dib or dbb designs available

suitable and proven for high-cycle operations

anti-static device

anti-blow out stem

self-relieving seats

independent secondary stem seal tests

low fugitive emission packing

manual or actuated operation (electric/pneumatic/hydraulic)

designed for rapid operation

testing & certification

• third party witnessed qualification

• firesafe qualification testing to iso 10497, api 6fa and api 607

• fugitive emission testing to iso 15848

• pressure equipment directive 2014/68/eu

• seat and gland endurance testing

• valve signature comparisons